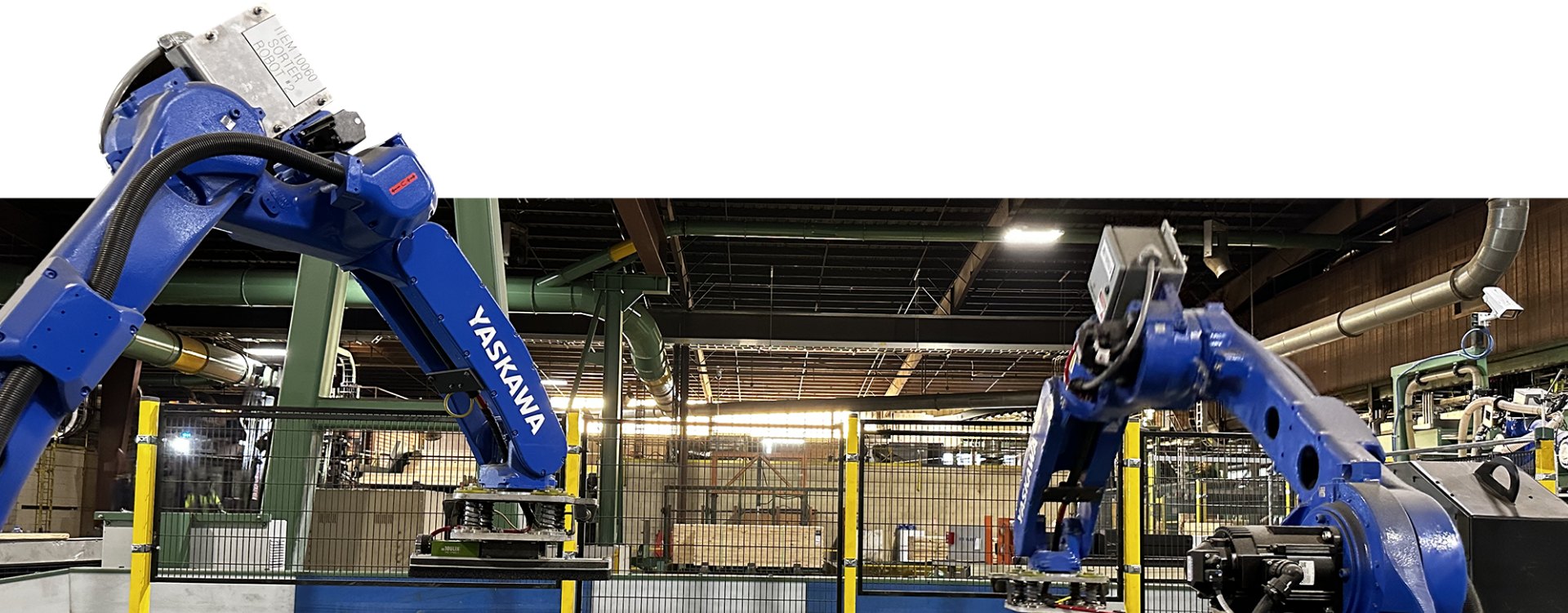

Comact’s AI-powered

robotic automation

A complete solution to intelligently pick, sort, and stack trim blocks and boards!

Comact’s robots are designed to pick and sort blocks and boards while also skillfully stacking them based on their grade and value, providing sawmills with unprecedented levels of precision, efficiency, and profitability!

The integration of ai is revolutionizing robotic operations.

- AI’s precision enables accurate block differentiation, whether blocks are close to one another or not

- Location detection: precisely locates blocks

- Efficiency boost: AI’s simultaneous operations lead to a more compact layout, simplifying operations with enhanced decision-making capabilities

- AI as a game changer: a transformative advancement using sophisticated deep learning, reaching new levels of robotic automation

- AI-powered vision grading: ensures that only valuable blocks will be sent to customers while maximizing recovery

More benefits

- Consistent decision-making

- Complex handling problem-solving with precision and efficiency

- Increased revenues and profits for a quick ROI

- Reduced labor costs

- Increased safety

Key features

- Provides a faster rate than traditional labor methods

- Easy installation and start-up (no need for specific knowledge)

- Operates continuously without breaks

- Sturdy installation with concrete base

- Safe environment with lock door switches on all gates accessible through local panel

- 6-axis robot allowing better reach and freedom of movement

Comact is a Yaskawa Motoman Strategic Partner. Yaskawa service is offered 24/7 in North America for all of Comact’s robotic systems.