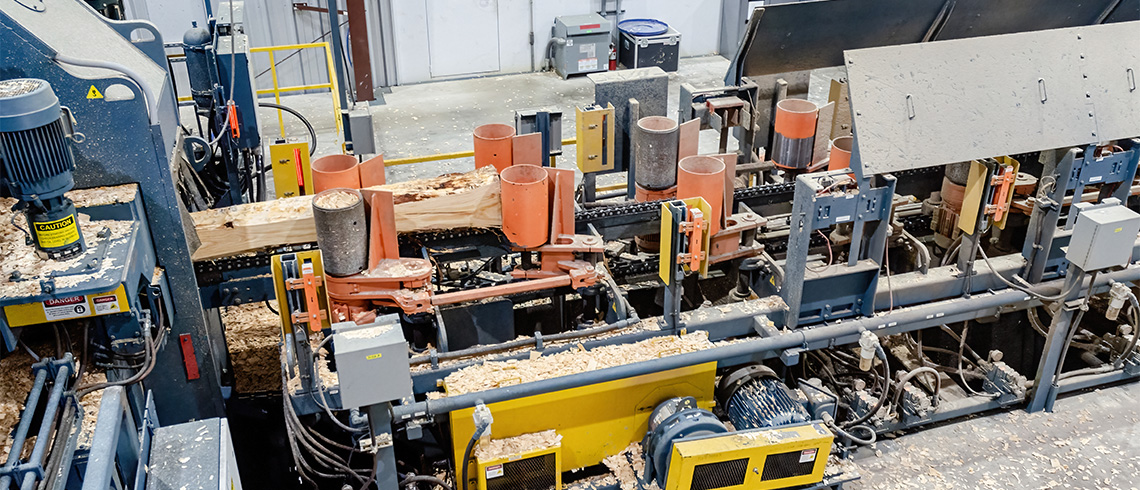

Primary Breakdown Closed-Loop Smart Tool

Product

description

Automates quality control during primary breakdown operations. The closed loop system automatically makes necessary dimensional adjustments in real time to ensure the optimized cant cutting pattern is executed to get the full value out of each log.

Benefits

- Problems or mechanical breakdowns identified and displayed on a dashboard in real time, and alerts sent

- Allows to determine smaller saw variation allowances for targeted size reduction

- Automated quality control reduces pressure on team members

Main

features

- Automatically corrects offsets to cutting tools (canters, profilers, saws) and infeed module

- Innovative Multi-offset Adjustment function speeds up the execution of adjustments and the correction of offsets

- Fastest closed loop reaction on the market for the definition of cutting patterns thanks to a strong mathematical model in the new Pattern Deduction function

Technical specifications

650 FPM

3" to 20"

6' Minimum

Hardwood

Softwood

Technologies and services to

enhance your production results