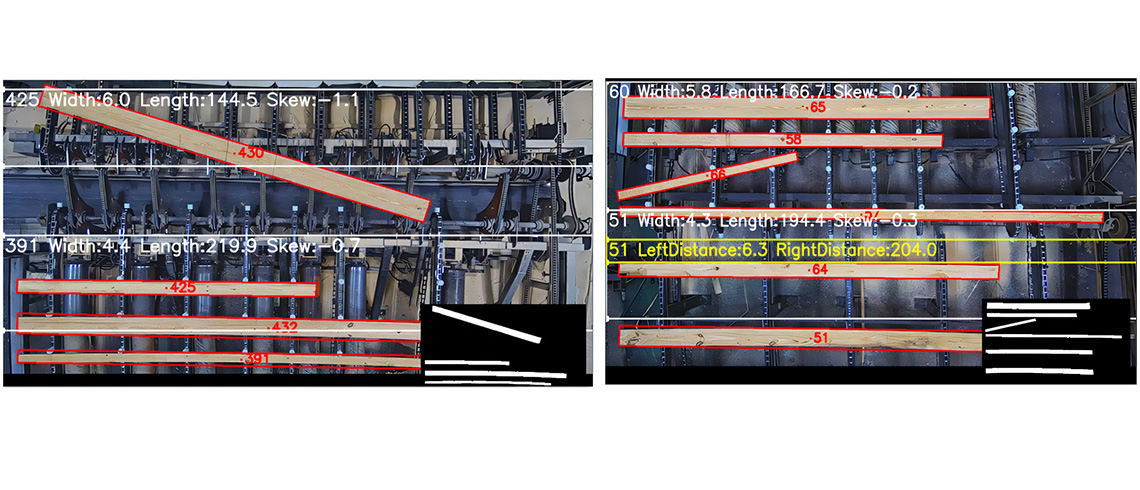

Smart Vision for Transverse Line Process Flow Monitoring

Product

description

Detects production anomalies such as stacked boards, jams, blockages, skewed boards, broken boards, boards that are too far from the line bar or too short (e.g., trim blocks), and more. Stops line when an anomaly is detected. Applies to any type of transverse process.

Benefits

- Improved process flow and reduced downtimes

- Safer environment as problematic situations are easier to manage

- Enhanced quality control

Main

features

- Faster production shutdowns; monitors 100% of the area, unlike photocells

- More accurate and reliable than photocells, which can be obstructed, canceled, or require cleaning

- Compares cutting length with optimized solution to detect any trimming issue

Technical specifications

330 LPM

Up to 28'

Max. thickness: 8'', max. width: 12''

(can be modified upon request)

Hardwood

Softwood

Technologies and services to

enhance your production results